Pharmaceutical manufacturing environments are highly complex with increasing requirements to minimizing human interaction inside the sterile manufacturing area. SRI has created a robot telemanipulation solution designed to perform telemanipulated operations including repair and maintenance in these sterile pharmaceutical manufacturing environments.

SRI’s history of telemanipulation success

SRI’s robot telemanipulation software allows users to control robotic arms as if they are an extension of their hands. With a highly intuitive user interface, the software requires minimal training for users to become proficient, allowing for quick adoption.

The telemanipulation software was created by the developers of the original DaVinci surgical robot, which is used around the world for complex lifesaving medical treatments. The SRI’s robot telemanipulation system incorporates many of the innovations that enabled the success of robotic-assisted surgery.

Since its creation, the system has been adopted for various other applications to eliminate the need for human presence in conditions or tasks that are dangerous.

Telemanipulation in pharmaceutical manufacturing

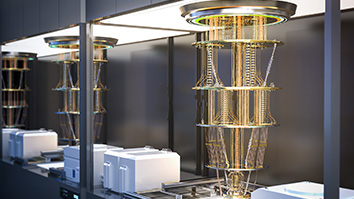

In today’s highly complex pharmaceutical manufacturing environments, minimizing human interaction with manufacturing is now a critical priority. SRI’s robot telemanipulation software solution integrates with third-party robot arms designed for the pharmaceutical industry, allowing for telemanipulated operations, including repair and maintenance in sterile pharmaceutical manufacturing areas, such as isolators and clean rooms.

Industry partnership

SRI has entered a strategic partnership with INVITE, a joint venture with Bayer Pharmaceutical and several other pharmaceutical companies, to accelerate the use of telemanipulation for repair and maintenance in sterile pharmaceutical manufacturing areas.

“SRI’s technology has enabled completely new possibilities for surgery. We are convinced that this type of intuitive and reliable teleoperation can also drastically change automation in the pharmaceutical industry. Completely eliminating product-human contact while maintaining the full skillset and adaptability of a human in-the-loop is invaluable, especially in clean rooms and isolators. INVITE aims to open up this solution space to the pharmaceutical industry. We have worked intensively on this technology in various research projects, but we are not a solution provider. With SRI we have found a strategic partner who has successfully demonstrated teleoperation with multi-million-dollar technology in surgery and will repeat this success in the pharmaceutical industry with standard robots. The industrial maturity and real-time capability of SRI’s technology we currently consider unrivaled,” said Charly Coulon, Head of Future Manufacturing Concepts, INVITE.

INVITE is a Research Center and Open Innovation Platform for innovative production technologies in the life science industry. Current research focus areas are Modular Production Units, Smart Robotics and Formulation Technologies. INVITE also leads the Drug Delivery Innovation Center (DDIC), an open consortium of partners from the pharmaceutical industry, suppliers and academia with a focus on multidisciplinary pre-competitive research in pharmaceutical technology.

Our work

- Taurus: This small robot is reaching new heights and solving once-thought impossible challenges

- Featured innovator: Thomas Low

- From the home front to the battlefield, providing access to lifesaving care

- 75 Years of Innovation: The Robotic Surgeon (Teleoperator System and Method with Telepresence)

Integration with robot arms designed for sterile environment

The telemanipulation software is highly flexible and designed to be integrated with third-party robot arms, allowing easy integration with robot arms that have been designed to operate in sterile pharmaceutical manufacturing areas, such as isolators and clean rooms.

Stereo video is streamed to the operator, allowing for real-time 3D vision. Additional information can be incorporated into the VR interface, such as a view from above, repair manuals and other data, to provide an augmented-reality environment for the operator. The system can also be configured to restrict actions that may cause damage to itself or other equipment.

SRI robot telemanipulation software provides a compact, precise and reliable customized solution to go where humans can’t or shouldn’t go, making once-impossible remote tasks a reality.

Get up and running

SRI’s telemanipulation software is being integrated with 3rd party robot arms so that pharmaceutical companies can test a number of use cases and proof-of-concepts. To find out how SRI’s system can help solve your big challenges that require telemanipulation, please fill our contact form or email customer.service@sri.com.