The intuitive telemanipulation software gives operators fine control over a robotic arm, allowing remote fixes without disrupting environments.

In pharmaceutical manufacturing, clean rooms are designed to minimize the risk of contamination from microorganisms, biomolecules, or anything else that might affect the safety and efficacy of the final product. These rooms are precisely controlled, but any time a person enters one to repair, maintain, or perform other tasks that are costly to automate, they potentially disrupt the sterile environment.

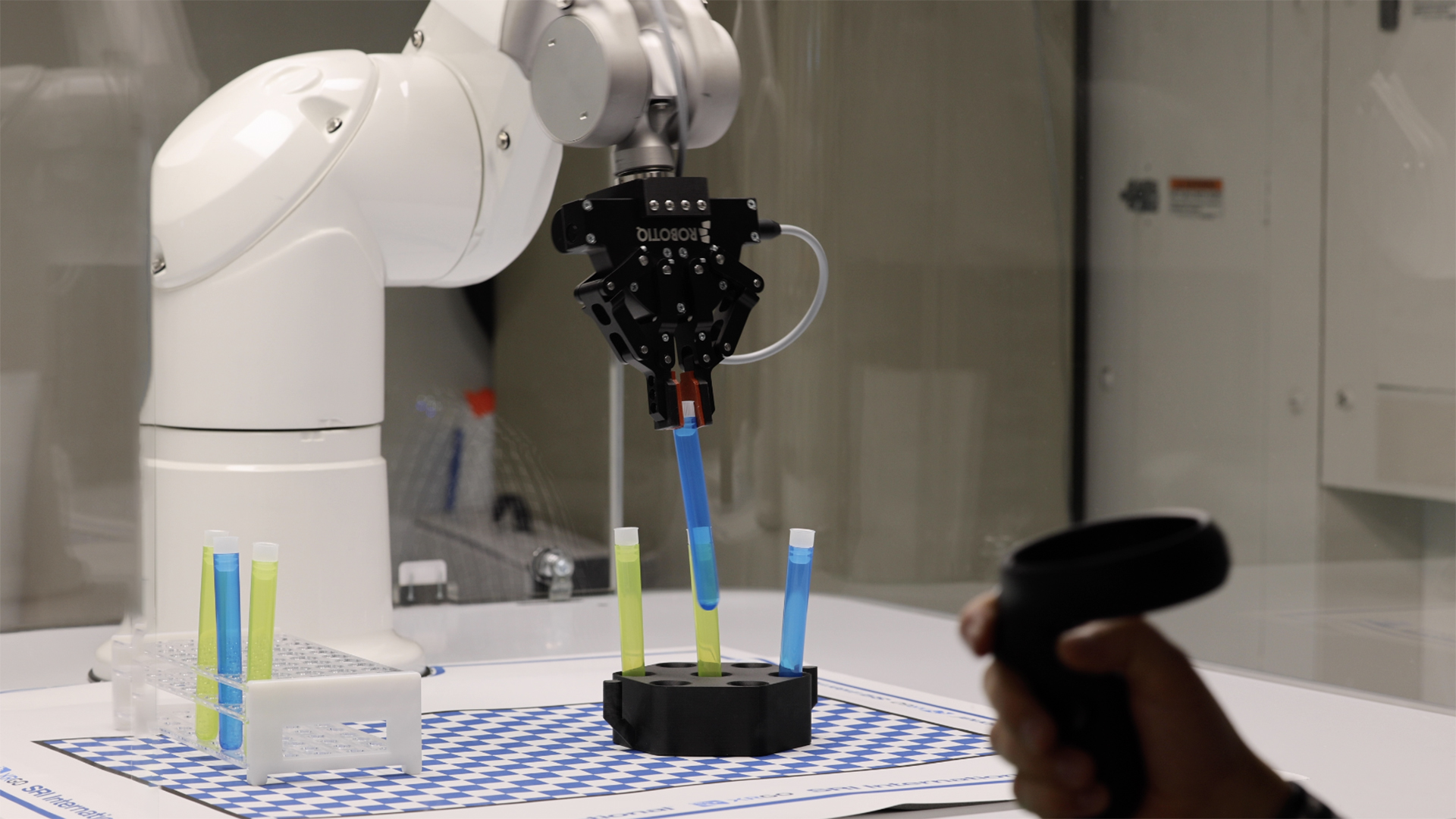

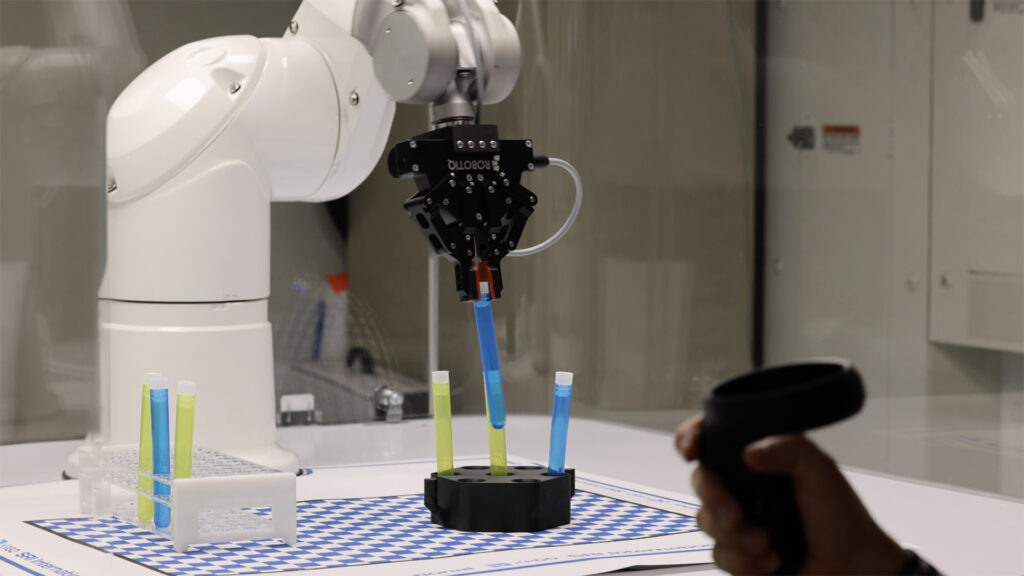

SRI’s XRGo robotic telemanipulation software could help people perform these tasks from a distance, protecting pharmaceuticals from contamination. XRGo allows operators to remotely control the movements of a robotic arm to, for example, adjust misaligned test tubes, or perform routine maintenance, without ever needing to enter the room.

“Automated processes require human oversight and occasional intervention. By allowing people to do this from outside of the room, we avoid having to endanger the pharmaceuticals or, in some cases, throw them out,” said Bill Rusitzky, Vice President of Business Development at SRI. “As much as possible, we want to remove interaction between people and the pharmaceutical product.”

“XRGo opens many possibilities for high-risk situations where we might have a robot on standby — the more hazardous the environment, the more useful this will be.” – Bill Rusitzky

Remote manipulation can help protect people from potential interactions with hazardous products. “Removing people from various situations is critical and this technology has the added benefit of opening jobs to people who are not physically able to perform tasks in person,” Rusitzky said. “The pharmaceutical companies that we’re working with agree that this is something that the industry needs to do, and they’re excited about XRGo’s potential.”

XRGo requires very minimal training and is elegant to use. The software streams live 3D stereoscopic video to an operator’s headset. The interface allows operators to switch between multiple views, create a 3D model of the arm’s orientation, and access information such repair manuals. The movements of the robotic arm are seamlessly linked to the movements of the handheld controller, which can provide haptic feedback to the operator. The result is a system that pairs gracefully with existing robot arms that are rated to function in sterile environments and is easy for anyone to learn.

“We have been looking for a telemanipulation solution that can minimize human contact with sterile areas of pharmaceutical manufacturing,” said Charly Coulon, Head of Future Manufacturing Concepts at INVITE, a joint research venture with Bayer Pharmaceutical and several other companies. SRI has entered a strategic partnership with INVITE to accelerate the use of telemanipulation in the pharmaceutical industry. “With SRI’s XRGo software, we found a great system with unmatched technical readiness and demonstrated compatibility with pharmaceutical robotics.”

Right now, XRGo is available for purchase to test various use cases in pharmaceutical labs. SRI is exploring additional uses for XRGo including food processing, all clean rooms, bomb disposal, dangerous industrial environments, maintenance in high-risk aspects of the energy sector, and others. “XRGo opens many possibilities of remote repair work for offshore oil or other high-risk situations where we might have a robot on standby,” Rusitzky said. “The more hazardous the environment, the more useful this will be.”

Get up and running

SRI’s telemanipulation software is being integrated with 3rd party robot arms so that pharmaceutical companies can test a number of use cases and proof-of-concepts. To find out how SRI’s system can help solve your big challenges that require telemanipulation.