The 75 Years of Innovation series highlights the groundbreaking innovations spanning from SRI’s founding in 1946 to today. Each week, SRI will release an innovation, leading up to its 75th anniversary in November 2021.

A plastic that overtook Kevlar in the 1980s as the world’s strongest polymer.

Strong stuff: How SRI International gave the world the strongest plastic

In chemistry classrooms worldwide, teachers demonstrate chemical reactions to make their lectures more engaging and exciting. One demonstration that never ceases to amaze students is the reaction that creates polymers. Two chemical solutions — adipoyl chloride and hexamethylenediamine — are combined in a beaker. A reaction occurs. The teacher inserts a glass rod into the mixture and pulls out a long string of plastic, specifically Nylon polymer. Nylon was first developed in the 1930s. Fifty years later, SRI International developed a new polymer that was given the name Zylon. Zylon was notable for being the world’s strongest polymer.

The strongest polymer on Earth

Recently, plastic has had a bad reputation, primarily because of ocean pollution. Surprisingly, plastic was originally developed for ecological reasons. It was developed to replace natural materials taken from living creatures, such as shellac and ivory. As scientists developed new plastics, they became increasingly a part of everyday life. For example, Nylon was used in the 1930s and 40s to replace silk and other natural resources in the manufacture of parachutes, ropes, and even body armor, in support of the war effort. By the 1960s, plastic had taken on cosmic proportions, playing an important role in spaceflight.

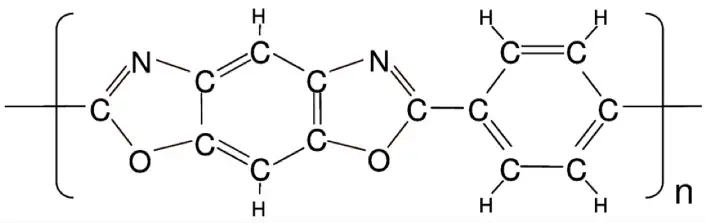

As plastics continued being developed and evolved, in the 1980s, SRI International began work on a new polymer, poly(p-phenylene-2,6-benzobisoxazole), abbreviated as PBO. PBO is made by a method known as condensation polymerization, a process in which molecules combine while simultaneously losing small molecules, such as methane or water. The two starting materials in the synthesis of PBO are 4,6-diamino-1,3-benzenedoldihydrochloride (DABCO) and terephthalic acid (TA).

The synthetic polymer created, a gold-colored fiber, was patented and commercialized by the Toyobo Corporation as Zylon®. At the time, Zylon was the strongest human-made polymer on earth, with a tensile strength of 1.6 times that of Kevlar. PBO polymers were also the first human-made organic fiber in which the cross-sectional strength outperformed both steel and carbon fiber.

Zylon is a thermosetting polymer. Unlike thermoforming plastics, which can be heated and shaped multiple times, a thermosetting polymer can only be heated and shaped once; the heating process hardens and cures the polymer into its final and permanent form. This characteristic contributes to Zylon’s superpowers among polymers, namely:

- Thermal stability: Zylon’s melting point is above 1470° Fahrenheit (780°C).

- Super strength: Zylon is 1.6 times stronger than Kevlar.

- Flame resistance: Zylon resists combustion, requiring conditions above 68% oxygen.

Putting Zylon to use

Having super strength gave Zylon versatility: Zylon found applications in several areas, including:

Formula One Racing: Zylon has used to affix the wheels to the car’s chassis, create anti-penetration panels for the car’s cockpit, and strengthen racing-helmet visors.

Body armor: Because Zylon is lightweight and very strong, it is a perfect material for body armor. In the 1990s, Zylon was used in bullet-proof vests.

Mar Exploration Rover parachute: NASA uses a mix of plastics in its Mars Exploration Rover modules, including Nylon, Kevlar, and Zylon. NASA uses braided Zylon for the spacecraft’s parachute harness.

Racing yacht rigging: Zylon is used in the standing rigging of modern racing yachts, resulting in rigging that is 65% lighter and has superior durability than other materials.

Seeing plastic through a different lens…

SRI International has a long history of developing polymers like Zylon. For example, in the early 2000s, SRI developed the electroactive polymer artificial muscle (EPAM), which has many medical applications.

The need for exceptional materials means that human-made synthetic polymers are unlikely to disappear. And as humans grapple with climate change, the redundancy of plastics may not be the answer. The World Economic Forum recently examined how plastics can be used for the good of the world, concluding that:

“Plastic isn’t just rubbish: it could actually be a driver for transforming regional relationships and inspiring true collaborations founded on circular economy principles. The opportunity is there; we just have to look through a different lens.”

Looking through a different lens is a guiding principle for SRI International. SRI will continue to innovate to make plastics that enhance, not hinder, the lives of humans on the planet.

Resources

The Dish, Artificial Muscle Electroactive Polymer (EPAM): https://medium.com/dish/75-years-of-innovation-artificial-muscle-118ab5d62f8

World Economic Forum, We can use plastics to change the world for the better: https://www.weforum.org/agenda/2019/12/plastics-change-the-world-circular/

NASA, Mars Exploration Rovers: https://mars.nasa.gov/mer/mission/spacecraft_edl_parachute.html