The 75 Years of Innovation series highlights the groundbreaking innovations spanning from SRI’s founding in 1946 to today. Each week, SRI will release an innovation, leading up to its 75th anniversary in November 2021.

A low power, lightweight replacement for older CRT technology allowing the development of modern flat-panel displays

The incredible shrinking panel display: How SRI International gave the world flat panel displays and more

Often, the technologies we take for granted, like the humble laptop screen, are a product of decades of research. The flat panel screen these words are appearing on began its life as an SRI International inspiration to flatten displays. The science and engineering behind this technology are a mix of ingenuity and natural phenomena.

One of the reasons old televisions (TVs) were so large is because they used Cathode Ray Tubes (CRT). CRTs are big beasts. A CRT requires a vacuum and large voltage to facilitate the movement of a beam of electrons. SRI came up with a way to reduce the size and optimize the capacity of field emission cathodes to give us the flat displays we use today. This is the story of the incredible shrinking panel display.

From quantum tunneling to vacuum microelectronics

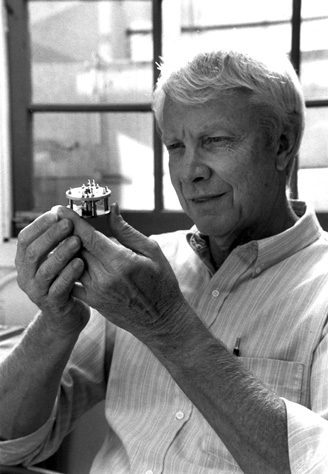

The Spindt cathode field emission technology namesake is Charles A. Spindt, also known as “Capp”. Capp set his mind and heart on changing the requirement for the thermionic generation of electrons that traditionally used a hot filament — resulting in the orange glow seen in vacuum tubes. One alternative, the cold cathode field emitter, avoided the hot filament but required a voltage of thousands of volts to operate. Dr. Spindt developed micro-scale emitters able to produce field emissions requiring less than 100 volts. This paved the way for the new, highly efficient, ‘cold cathodes’. These cold cathodes were based on a technique called ‘field emission amplification’ (FEA).

FEA facilitates electron emission under a low anode — cathode voltage difference by using points or tips: They work somewhat like a lightning rod… Under the influence of potential difference (aka the anode-cathode voltage difference), a high electric field forms around the tip of a cone. This promotes the ejection of a field of electrons used to form the electric current flow as part of the display process. These tips are made from a variety of materials, including molybdenum, silicon, gallium arsenide, zirconium carbide and so on. The cathodes originally fabricated by Spindt and his team used closely packed cone arrays containing between 100 and 5,000 cones of molybdenum. This became known as the “Spindt Field Emitter Array”.

Spindt made the first gated FEA’s using microfabrication technology.

The science behind the technology is worth exploring briefly. Quantum tunneling, which vacuum microelectronics depends on, and the flat screen is a result of, is one of the universe’s amazing natural phenomena. Quantum tunneling happens when an electron passes through a substance, such as silicon, that you might otherwise think would present a barrier. This happens because the scale of an insulator (like silicon), at the atomic level is normally such that quantum mechanical effects come into play. The electrons generated by an FEA are affected by the quantum effect known as “Heisenberg’s Uncertainty Principle”: That is, an object at the quantum level can be both a wave and a particle. It is this property that allows electrons to “tunnel” through seeming barriers.

It is worth noting that this property can also cause problems in modern electronics, as electrons can ‘leak’, the scale of the circuitry being so small.

Cold cathodes create hot technology

Spindt and team were originally funded by SRI’s internal funding. However, in 1973, NASA’s Lewis Research Center stepped in with additional funds to take the research to the next level. Ivor Brodie, a known expert in vacuum-tube technology, joined Spindt at SRI. Brodie was tasked with publicizing the advances in the cathode field emission technology. In 1985, the Laboratory of Electronics and Information Technologies (LETI) announced early results in the development of a flat panel, field emission display (FED) based on the Spindt cathode. Soon the field took off and companies across the world worked to commercialize the technology developed by SRI.

The non-thermionic method of generating electron fields is perfect for other applications and use, including in space and other extreme conditions. Other suggested applications of cold cathode technology include scanning electron microscopes and mass spectrometers.

When you next carry a lightweight laptop to work or watch a TV hung from a wall in your living room remember it started with a team at SRI with a dream of shrinking the screen.

Resources

1st IEEE International Vacuum Electronics Conference, 1988

Patent US3755704A, Field emission cathode structures and devices utilizing such structures: https://patents.google.com/patent/US3755704A/en

Nation, John & Schächter, Levi & Mako, Rick & Len, L.K. & Peter, William & Tang, Cha-Mei & Rao, Triveni. (1999). Advances in cold cathode physics and technology. Proceedings of the IEEE. 87. 865–889. 10.1109/5.757258.

Spindt, C. A. (1976). “Physical properties of thin-film field emission cathodes with molybdenum cones”. Journal of Applied Physics. 47 (12): 5248–5263. Bibcode:1976JAP….47.5248S. doi:10.1063/1.322600.